BOLTRAKK®

Fasteners monitoring

BOLTRAKK® solution is an innovation from JPB Système designed to monitor tension in bolted assemblies. By effectively managing fastener tension, you enhance the security of your business. This allows you to plan maintenance proactively and achieve greater overall efficiency.

BENEFITS

DESCRIPTION

In the industrial sector, assemblies face extreme conditions, including vibrations, repeated stress, temperature variations and shocks, often leading to nut loosening. Industries typically investigate to solutions like bolt locking or implement periodic maintenance to avoid accidents and potential injuries, incurring significant down time and costs.

With our solution, you can eliminate periodic checks and tighten fasteners only when necessary, optimizing efficiency and reducing costs.

HOW IT WORKS

JPB Système has developed specialized strain gauges that enable the size reduction of the sensor. Installing the sensor in your assembly is straightforward. The sensor is equipped with smart electronics that process and convert measurements into a robust signal, unaffected by communication distance or temperature variations. This ensures a high level of accuracy across the entire operating range.

To complement this technology, JPB Système has also developed a data acquisition system and display solutions tailored to your specific needs:

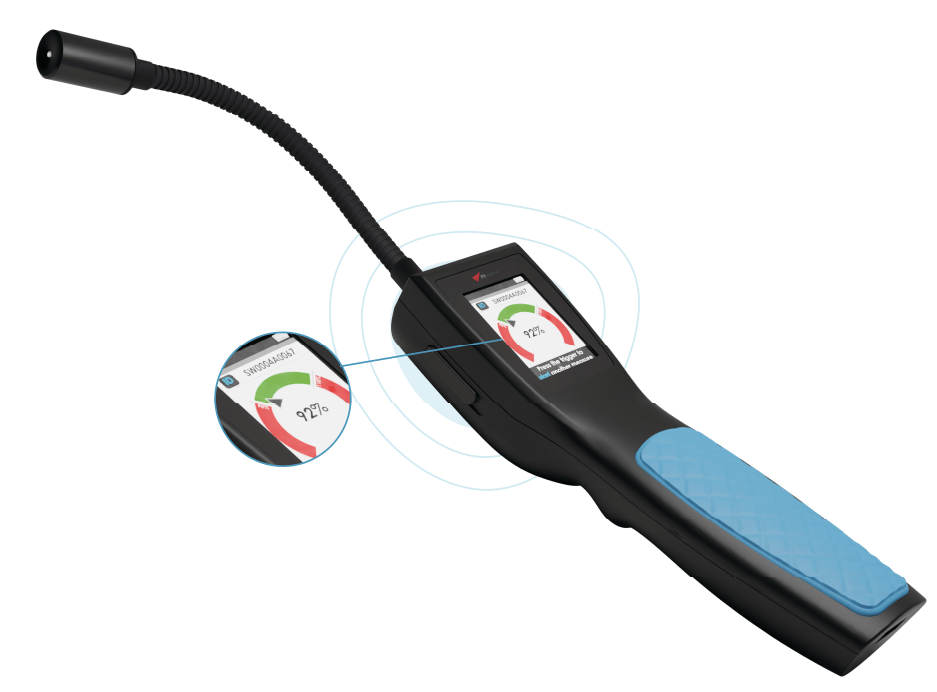

RFID BOLTRAKK® SENSOR & READER

RFID BOLTRAKK® SENSOR & READER

• Manual control

• Suitable in safety-sensitive environment (not connected to the Internet)

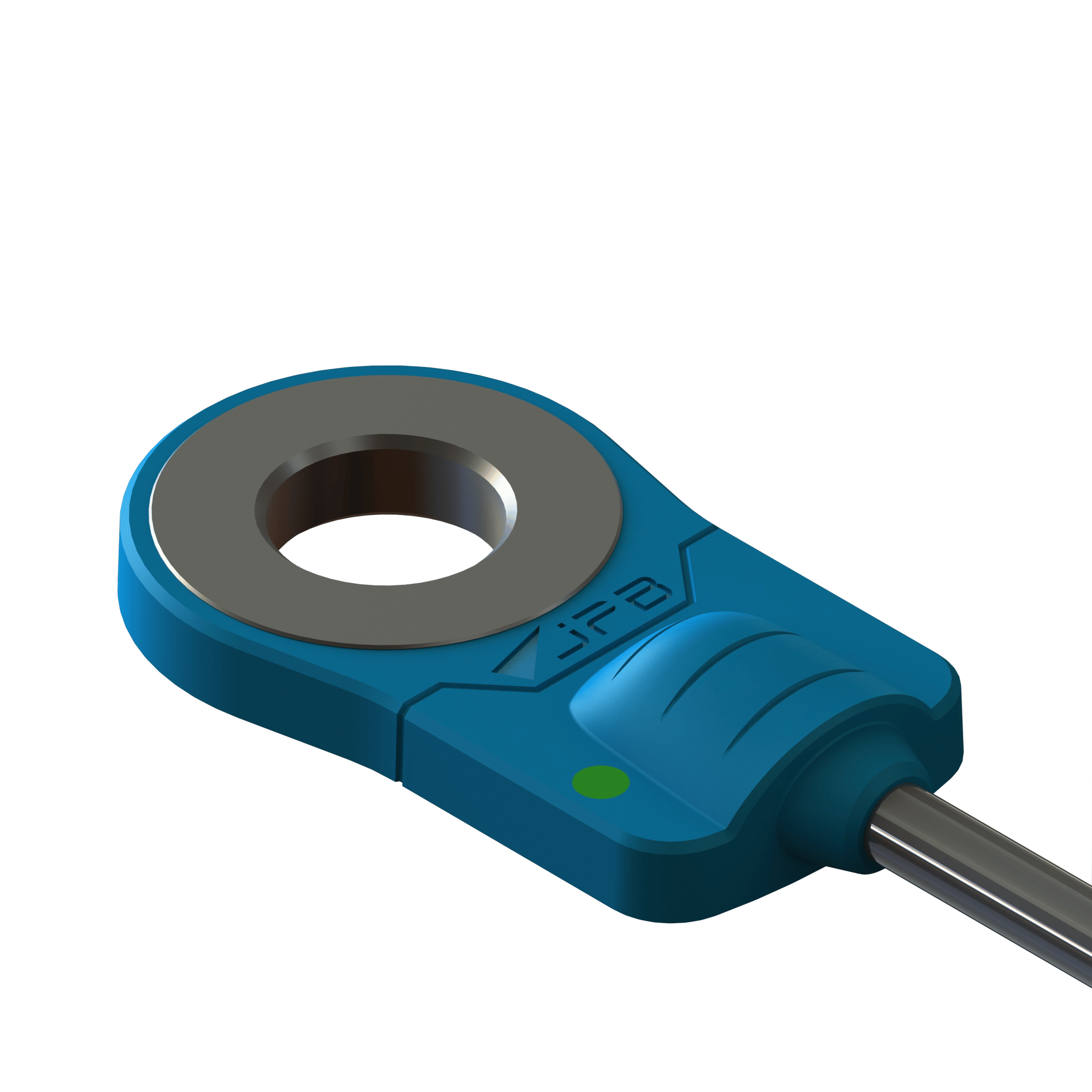

WIRED BOLTRAKK® SENSOR & APP

WIRED BOLTRAKK® SENSOR & APP

• Automatic and remote control

• Data available at any time (IoT)

2 SOLUTIONS EASY TO USE

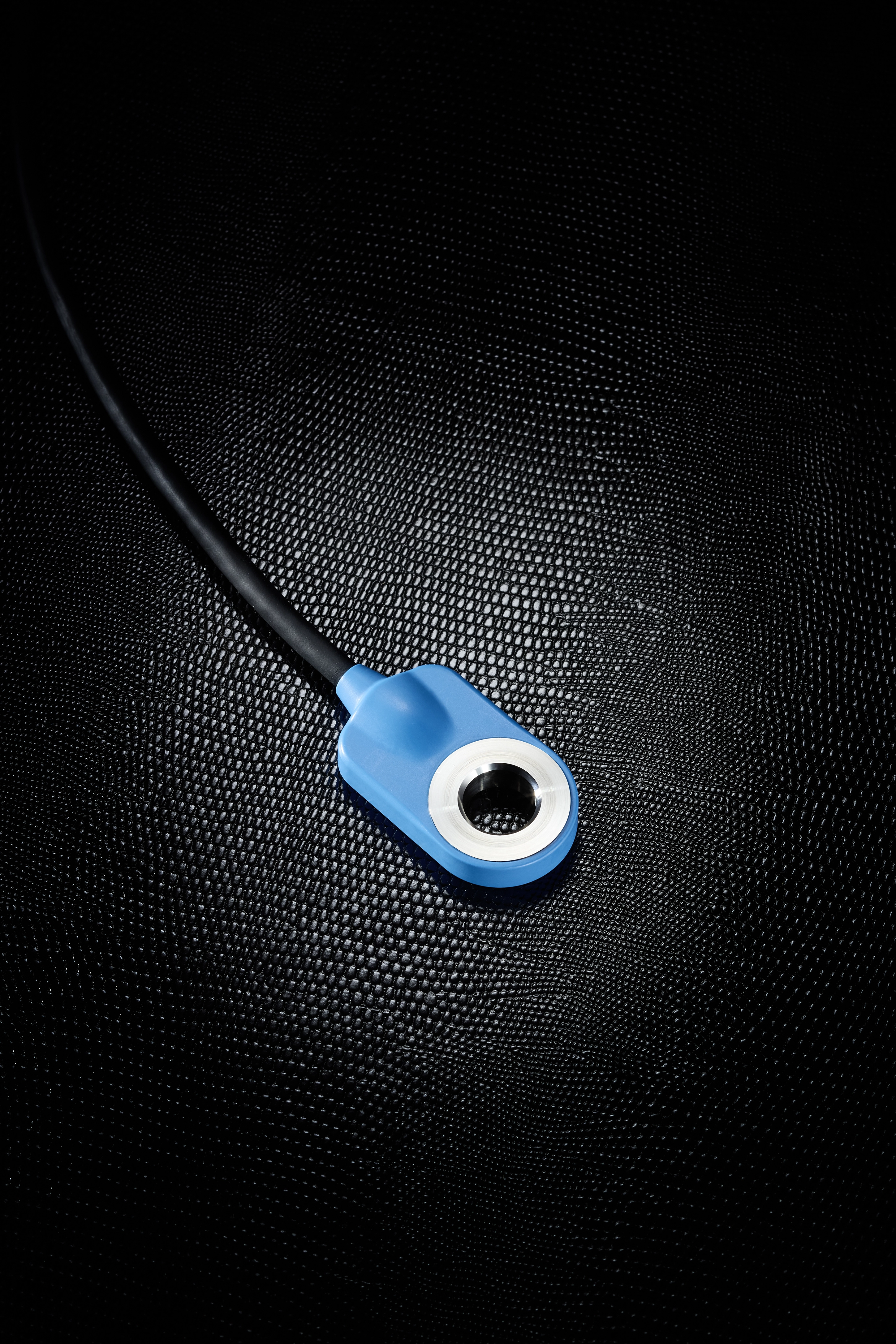

Place the BOLTRAKK® Sensor on the non-rotating part of the fastener, such as the screw head or nut. Tighten the bolt using your torque wrench as usual. There is no need to change your torque process.

Once the bolt is properly tightened, establish the '100%' level using the reader or the app. At any point, you can check the tension variation in the fastener: perform a manual check with the reader (RFiD BOLTRAKK® Sensor) or a manual/automatic and remote check with the app (Wired BOLTRAKK® Sensor).

RFiD BOLTRAKK® Sensor + Reader

RFiD COMMUNICATION

NO BATTERY

MANUAL CHECK

DATA STORED IN THE SENSOR

ON-SITE CHECK

WIRED BOLTRAKK® SENSOR + APP

MOBILE NETWORK COMMUNICATION

24V OR 230V POWER SUPPLY

MANUAL OR AUTOMATIC CHECK

DATA STORED IN THE CLOUD

ON-SITE OR REMOTE CHECK

“By developing BOLTRAKK® with users, we addressed some important observations and integrated appropriate features in our tension sensor to further improve its functionalities. This collaborative development improves significantly the accuracy and safety across MRO operations (Maintenance Repair & Overhaul)."

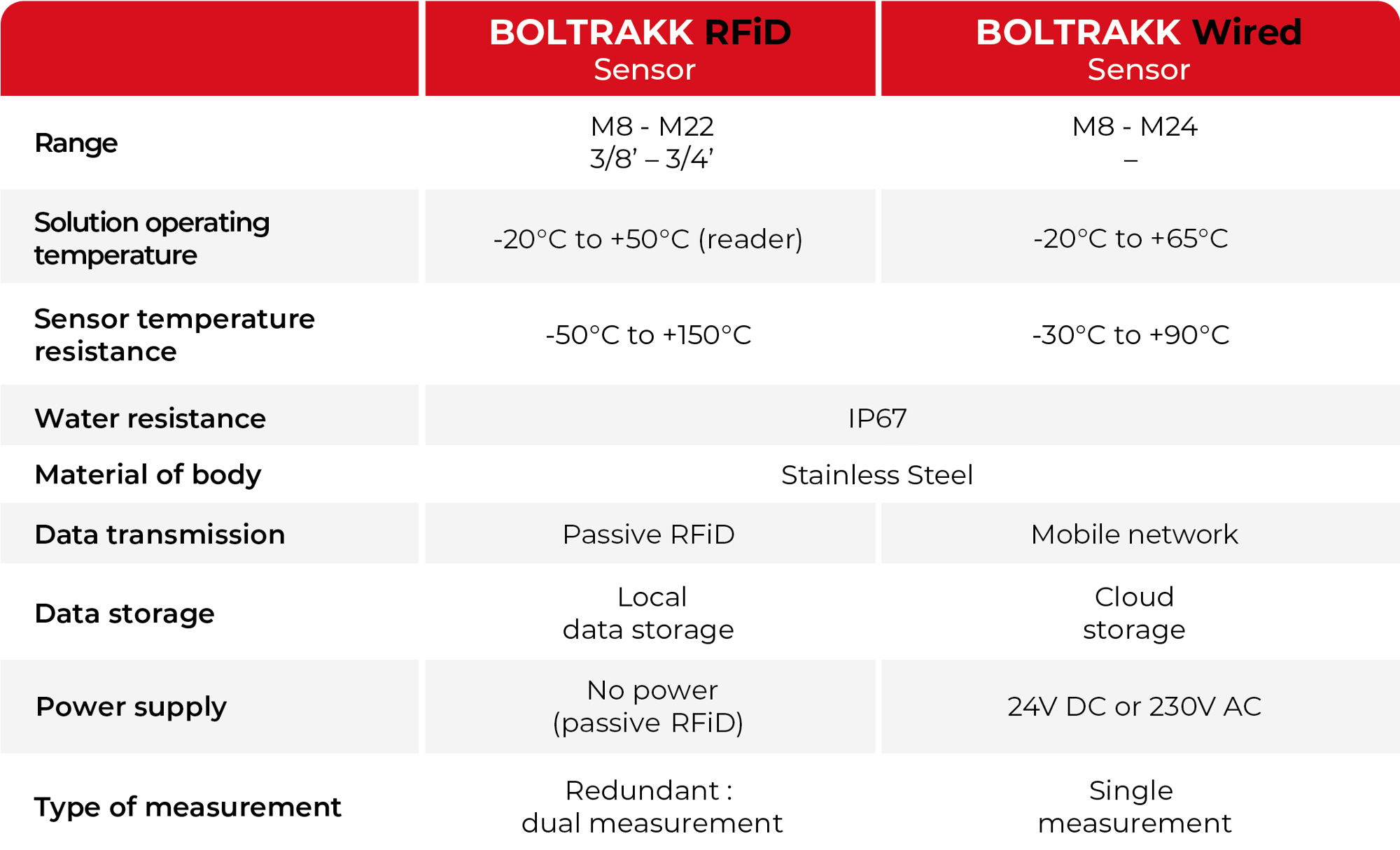

TECHNICAL FEATURES

RESISTANCE

Our sensor, electronics, elastomers, and antennas undergo rigorous testing in harsh conditions, including vibrations, drops, shocks, chemical solvent exposure, and UV resistance. We conduct thorough checks at every stage of manufacturing to ensure a high level of quality and reliability.

PASSIVE DEVICE

ASSEMBLY SAFETY

HUMAN FACTOR MITIGATION

REDUNDANT MEASURE

EASY TO USE

TIME SAVING FOR MAINTENANCE