ABOUT US

INTERNATIONAL PRESENCE

OUR COMPANY HISTORY

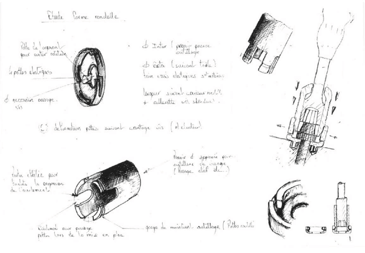

During the Paris Air Show, Jean-Pierre MARC, Damien MARC's father, is challenged by SNECMA (now Safran Aircraft Engine) to find a solution for removing lock-wire from borescope plugs on aircraft engines.

Jean-Pierre MARC and Bernard BARRE create JPB Système.

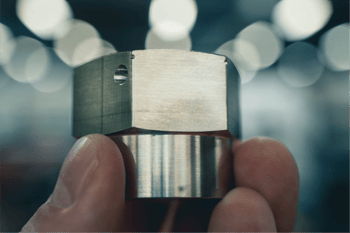

JPB Système obtains certifications for its self-locking solutions designed for the GE90-115 engine (used in the Boeing 777) and the G7200 engine (used in the Airbus A380).

After Jean-Pierre MARC unexpectedly passed away, his son Damien MARC takes the role of Director of the company.

He establishes three strategic pillars: ongoing product innovation, accelerated market expansion to other countries and aircraft manufacturers, and production expertise. His guiding principle is 'deliver 100% on time with 100% quality'.

To expand our business in North America, we establish a commercial office in Cincinnati, OH.

JPB Système becomes part of the prestigious circle of 'BPI Excellence'.

Additionally, we receive the Innovation Award from INPI, the prestigious French National Institute of Intellectual Property.

JPB Système secures a 30-years contract with Rolls-Royce to provide equipment for the TRENT Engine family and patented a new self-locking borescope plug designed to withstand extreme conditions.

Concurrently, we establish a new plant to accommodate the growth in the aeronautic sector in Villaroche, located in the south of Paris.

JPB Système secures a contract with SAFRAN Aircraft Engine and earns the award for the fastest-growing aeronautic company.

JPB Système registers a new patent for a revolutionary lockwireless fluid fittings B-nut application. This self-locking fitting is named LULYLOK™.

To accommodate the increase in customer orders, Damien MARC decides to double the size of the plant in Villaroche.

JPB Système also receives the award for 'Industrial Performance' of the year.

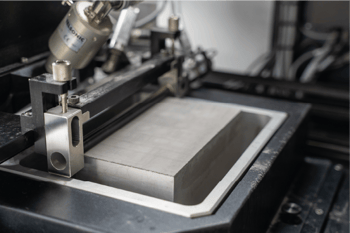

The company establishes a unique robotics machining line with 100% automated inspection. The entire manufacturing process can be managed from a smartphone. Additionally, the company secures a Long Term Agreement (LTA) with Pratt & Whitney and achieved the 8th consecutive award for being the Best SAFRAN supplier.

JPB Système inaugurates a mirror production plant in RZESZOW, near KRAKOW, situated in the aviation valley in Poland, ensuring business continuity for our customers.

Additionally, we initiate investments in additive manufacturing, specifically metal 3D printing technology (MBJ).

Creation of KEYPROD: a startup with digital expertise. KEYPROD is a unique plug & play production monitoring solution.

JPB Système seizes the crisis period as an opportunity to accelerate products development by hiring top-class engineers in R&D and preparing for the business recovery. Notably, no employee were laid off.

JPB Système introduces an innovative solution for bolt tension monitoring, combining mechanical and electronic expertise.

The Smart Program assists industries dealing with bolt loosening or requiring periodic tightening checks.

Users benefit from time and cost savings, automatic tension records and a transition to predictive maintenance.

We are inaugurating a larger facility in the heart of Aviation Valley (from 1500 to 4000m2), bringing our services closer to our customers. This site anticipates the growth of the aerospace industry and its future needs.

At the same time, we are strengthening our digitalization efforts with the DmaasT project and a dedicated manager and we are recruiting a digitalization expert

THE POLISH SUBSIDIARY

The mirror production site, established in 2018 in the Polish Aviation Valley, ensures business continuity to our customers. A new building is set to open in Rzeszow in 2024.Meeting at BIG 2020

Following the Covid crisis, Damien MARC had the opportunity to talk to Emmanuel MACRON, French President, and Mr Kenyatta, former President of Kenya, about the incredible journey JPB Système took during the pandemic.

OUR CSR COMMITMENTS

- +250 volunteers,

- +70.000€ of donations received to finance transport,

- +70 trucks sent to our premises in Rzeszow in 6 weeks.

OUR HUGE SUPPORT FOR UKRAINE

In 2022, we mobilized to assist Ukraine with the resources at our disposal. Leveraging our Polish site near the border, we utilized our transport network to contribute to the country rescue on our own scale.

- Environment

- People's right

- Working conditions

- Loyalty

- Local development

Respect for the environment

Identification and reduction of odor nuisances

Respect for people's right

Monitoring illegal employment

Preventing and fighting any type of discrimination

Gender equality action plan signed in 2021

Protection of employee and customer data

Responsible working conditions

Material conditions, comfort and well-being at work (assured during mid-year interviews, individual interviews and self-monitoring audits)

Clear organization and management (organization chart)

Remote work

Clear and regular internal communication

Career planning

Skills development / training

Employability

Internal equity (action plan for gender equality in the workplace)

Access to disabled workers

Enhancing apprenticeship

Sports lessons with a coach

Fair practices

Ethics in competitive bidding

Ensuring fair competition

Respect for intellectual and industrial property

Ethical influence management

Implementing a quality approach (ISO9001 and EN9100 certification + NADCAP for welding)

Innovation (R&D department)

Accessibility of products and services

Community and local development

Local vocational training (Seine-et-Marne)

Help with integration

Local purchasing (local suppliers)

French Fab member

OUR BUSINESS AREAS

We introduced additional self-locking solutions and explored opportunities in various sectors. Today, we operate across diverse industries and can assist any business facing bolt-related challenges.

Box Description