MBJ

Metal Binder Jetting

This additive manufacturing process streamlines the production of industrial parts.

DESCRIPTION

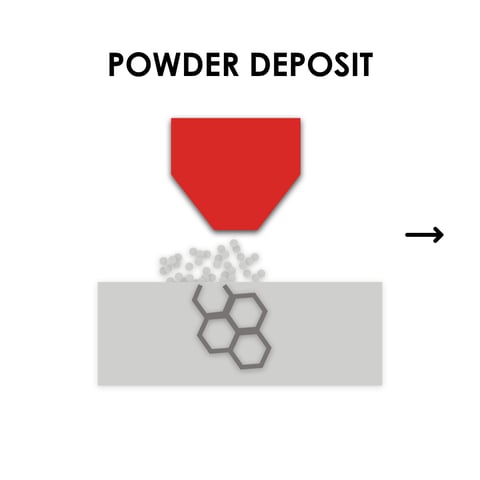

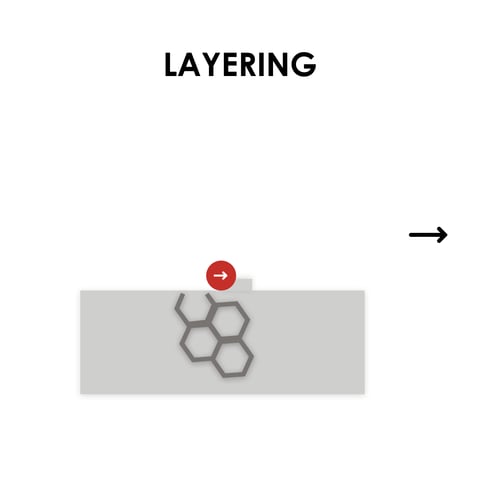

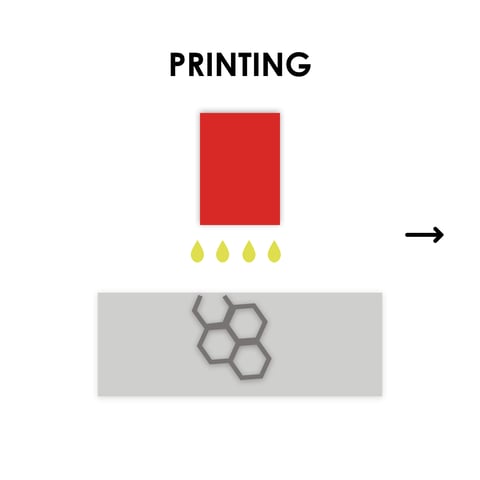

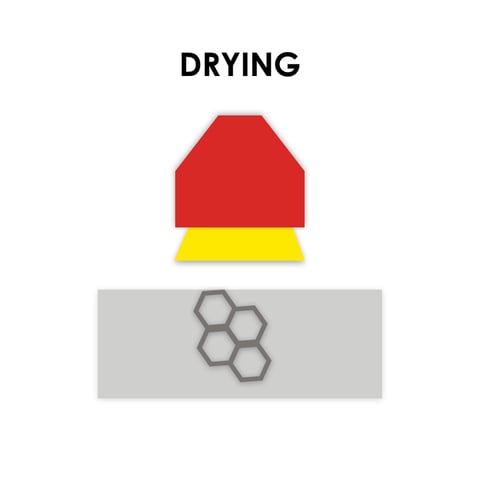

The Metal Binder Jetting process involves selectively consolidating a powder bed with a binder, layer by layer, without melting. Each powder layer is printed by spraying a liquid binder in droplet form.

These droplets impact, wet and spread over the surface of the powder bed, facilitating the bonding of a large number of particles.

With this innovative process, it takes the same time to print 100 similar parts and 100 different parts for the same total print volume.

WHY DOES JPB SYSTEME INVEST IN METAL BINDER JETTING?

In the face of escalating production demands, JPB Système initiated a quest for a more flexible and innovative production method to address specific constraints. The ideal production solution needed to:

- Be suitable for production runs of up to 10,000 parts.

- Accommodate small parts (40/50mm) efficiently.

- Be applicable to non-rotating parts.

Additive manufacturing emerged as a viable solution to meet these requirements, offering enhanced production flexibility. Notably, the technology demonstrated consistent production times for 100 entirely different parts compared to 100 identical parts. This compelling advantage prompted JPB Système to undertake a scientific exploration, delving into the characteristics and future challenges of this additive manufacturing process.

Flexibility

100 different parts take the same time as 100 identical parts.

Save time

Stack parts in the job box.

Moving component

Print and sinter parts with moving components inside.

Save weight

With hollow shapes and optimized design that reduce weight.

jetting-processing.webp)

“This investment will allow us to confirm the results we have achieved in trials and stabilise the MBJ process for production. We believe that this technology will enable us to reduce production times for certain parts and speed up delivery times to customers. ”

BENEFITS

Innovation

Eliminates many assembly steps

Better management of raw materials

Save weight

Flexibility

Save time

THE 4 STEPS OF METAL BINDER JETTING